MOLDING

DOE Study

- Pressure Loss Study

- Short Shot Study

- Pressure and Speed Relative Viscosity Study

- Gate Seal Study

High Precision Over-molding

High Precision Insert-Molding

High-Temperature Molding – PEEK, Ultem, Radel

Cleanroom Molding Capabilities

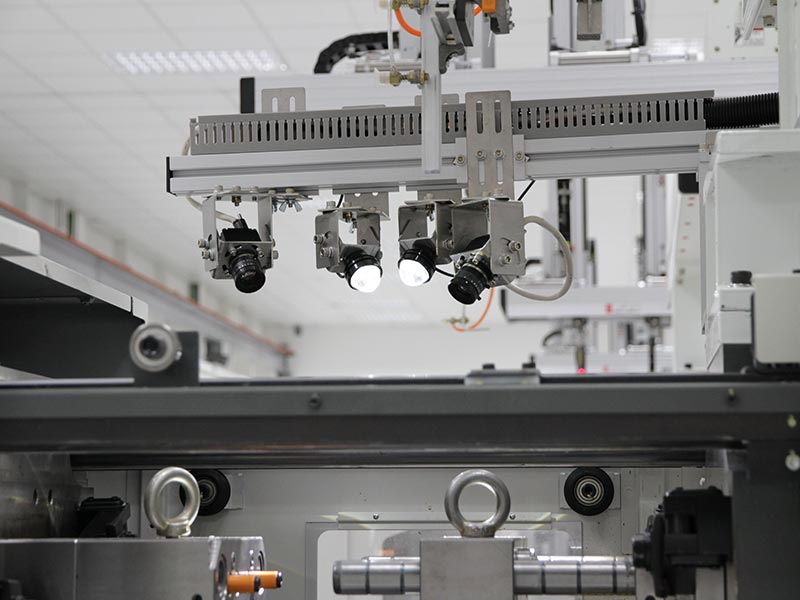

Robotics implementation for precision and efficiency

Material Versatility:

- Bio-Absorbable Polymers

- Implantable Grade Polyurethanes (PUR)

- Engineering Grade Thermoplastics (ABS, PC, etc.)

- Customer Supplied Resins

- Custom Colors

Equipment Versatility:

- Range from 25 tons to 450 tons

- 150 injection molding machines

Delta Asia has built a reputation for being a leader in producing high quality and complex plastic parts for many medical devices around the globe. Our expert Molding engineers partner with our customers to find the most efficient path to get parts into production to minimize both cost and time.

Based on Scientific Molding principles, Delta Asia has developed several areas of specialization including insert- molding, over-molding and processing of many different types of plastics that require specific handling such as optical polymers, high-temperature polymers, bioabsorbable polymers, implantable grade polyurethanes and many different types of engineering grades of thermoplastics.

Our molding department equipment consists of 150 state-of-the-art injection molding machines that range from 25 tons to 450 tons, Under the well-controlled production process, our machines are capable of producing small-volume parts for startups and high volume parts for mass production, and in a wide variety of sizes.